TCBs in use in Chernobyl New Safe ConfinementShow Full Screen

TCBs in use in Chernobyl New Safe ConfinementShow Full Screen TCBs in use in Chernobyl New Safe ConfinementShow Full Screen

TCBs in use in Chernobyl New Safe ConfinementShow Full Screen TCBs in use in Chernobyl New Safe ConfinementShow Full Screen

TCBs in use in Chernobyl New Safe ConfinementShow Full Screen Using TCBs in use in Chernobyl New Safe ConfinementShow Full Screen

Using TCBs in use in Chernobyl New Safe ConfinementShow Full Screen Chernobyl New Safe ConfinementShow Full Screen

Chernobyl New Safe ConfinementShow Full Screen Chernobyl New Safe Confinement installationShow Full Screen

Chernobyl New Safe Confinement installationShow Full Screen Chernobyl New Safe ConfinementShow Full Screen

Chernobyl New Safe ConfinementShow Full Screen Chernobyl New Safe Confinement installation using TCBsShow Full Screen

Chernobyl New Safe Confinement installation using TCBsShow Full Screen Chernobyl New Safe Confinement installation using TCBsShow Full Screen

Chernobyl New Safe Confinement installation using TCBsShow Full Screen Chernobyl New Safe Confinement installation using TCBsShow Full Screen

Chernobyl New Safe Confinement installation using TCBsShow Full Screen

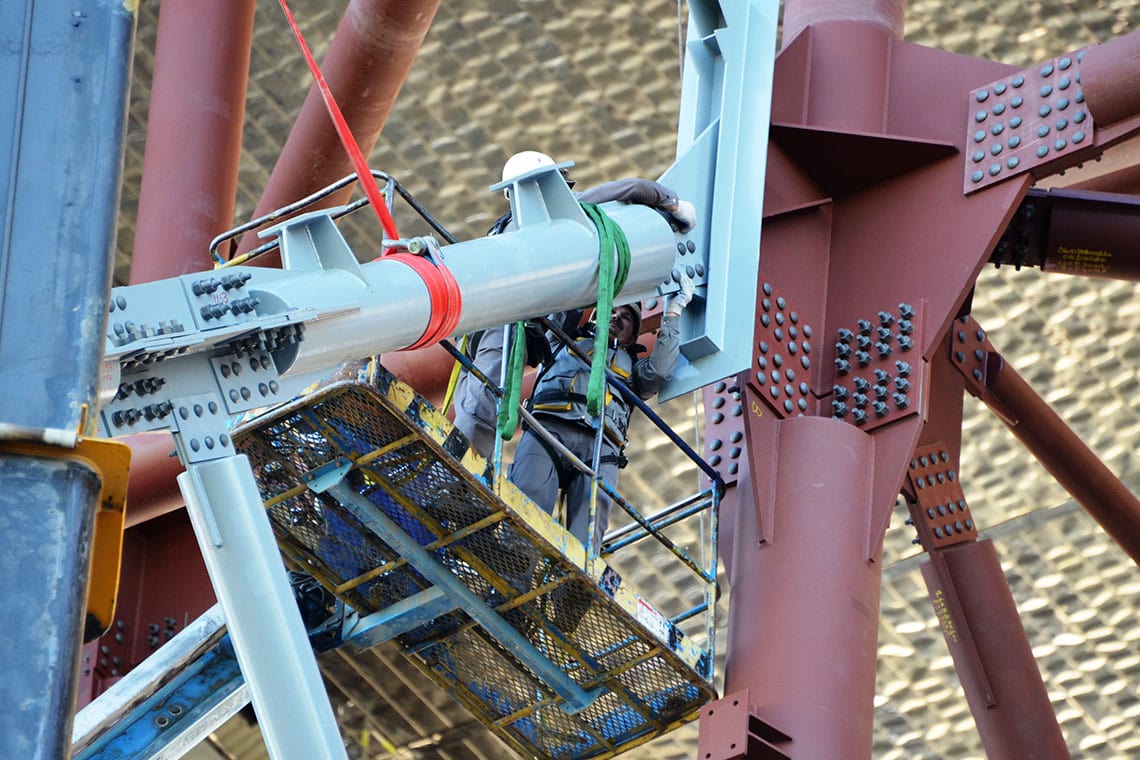

Chernobyl New Safe Confinement (NSC). There are over 650,000 Greenkote® Tension Control Bolts installed in this mega-structure protecting the planet from toxic radiation.

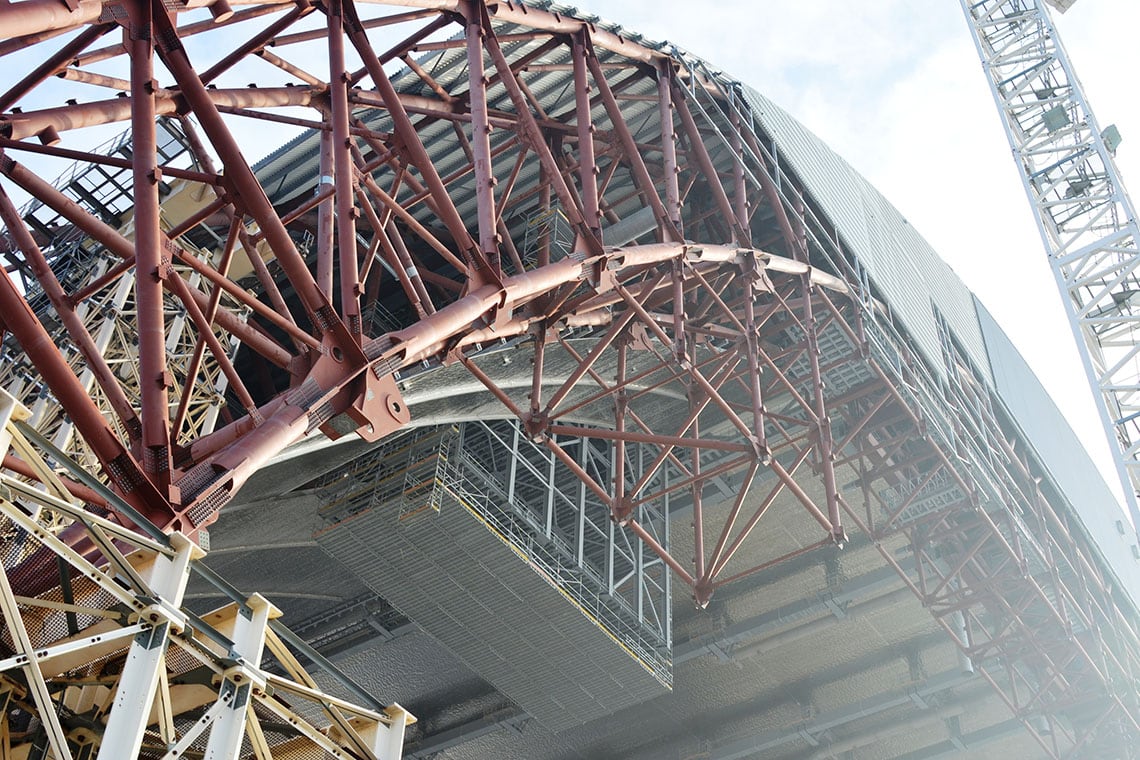

26th April 1986 saw the world’s worst nuclear disaster as an explosion at the Chernobyl nuclear plant allowed radiation to spread over large parts of the continent and sent plumes of radioactive dust as far away as Japan and the U.S. causing extensive pollution and long lasting ecological damage. Following the explosion, the reactor was encased in concrete to prevent the further spread of radioactive dust. Poor design, rushed execution and the passage of time contributed to the deterioration of the original coccoon, resulting in a heightened risk of radiation leakage.

Against this background, the Ukrainian government invited tenders for a new solution to prevent future radiation leakage as early as 1992, but it took a further 15 years before the design was agreed and the contract awarded to Novarka, a joint venture between Vinci Grand Projects and Bouygues Travaux Publics. Steel for the new structure was fabricated in Italy by Cimolai, with over 650,000 Tension Control Bolts needed to hold the structure together installed by steel erection teams from all over Europe.

The immense New Safe Confinement was designed to be built adjacent to the site and railed across. It is the largest movable structure ever constructed. A true ‘one-off’ design which came under tremendous vibratory pressures both in construction of the arch as well as during relocation. Research was conducted particularly looking into bolts and following extensive testing Novarka engineers determined that TCBs would be the best bolting assemblies to mitigate against this extreme vibration. The selection of Greenkote Tension Control Bolts was critical to the success of the structure.

TCBs are quick and easy to install and offer guaranteed tension which, together with visual inspection, removes the likelihood of operator error and ensures that connections are tightened in accordance with specifications. Nowhere was this more important than in the construction of the New Safe Confinement, where a rapid assembly speed was required to minimise workers’ exposure to radiation.

The Greenkote coating system on the Tension Control Bolts offered the designers of the New Safe Confinement important advantages, as it removed the risk of hydrogen embrittlement in high-strength bolts. Greenkote is also harder wearing than galvanising, offers excellent corrosion protection and readily accepts all paint systems.

Tim Stokes, Managing Director of Tension Control Bolts Ltd said, “Our ability to offer the combination of a fast and effective pre-loaded assembly system with bolts protected by Greenkote was a significant factor in determining the decision to use our product. Moreover, we are able to give a 150 years life time guarantee.”

Mark Gore, CEO of Greenkote added, “Greenkote’s thermal diffusion process offers exceptional corrosion protection and longer wear for Tension Control Bolts and it outperforms many other traditional coating processes such as zinc plating, mechanical and hot dip galvanising, metal flake and sherardizing as well as PVD and CVD. The Chernobyl project is a high point for us, as there can be few other applications where a high performance coating and protection system is so important when it comes to guaranteeing the structural integrity of a design.”

Taller than the Statue of Liberty and larger than Wembley Stadium, the behemoth 35,000 tonne mega-structure was successfully launched in 2017. Tension Control Bolts Ltd are justifiably proud of the critical role that every single bolt in this structure now has protecting our planet.

A video explaining the project in detail is available to watch on YouTube.

Photos courtesy of SSE Chernobyl NPP https://chnpp.gov.ua

Industrial & Commercial