Chemin de Fer du - LuxembourgShow Full Screen

Chemin de Fer du - LuxembourgShow Full Screen Chemin de Fer du - LuxembourgShow Full Screen

Chemin de Fer du - LuxembourgShow Full Screen Chemin de Fer du - LuxembourgShow Full Screen

Chemin de Fer du - LuxembourgShow Full Screen Chemin de Fer du - LuxembourgShow Full Screen

Chemin de Fer du - LuxembourgShow Full Screen

The new high-speed railway link between Germany and France will benefit European citizens from west and east alike, speeding up journey times and providing a more environment-friendly alternative to air travel on key routes.

The axis project will connect the high-speed rail networks of France and Germany, as well as to improve the railway link between France and Luxembourg. Its three parts are a new 300 km long high-speed, passenger-only rail line from Paris to Baudrecourt (near Metz) with a commercial speed of 320 km/h; upgrading of the Saarbrücken–Mannheim section (on the Paris– Metz–Frankfurt–Berlin railway corridor and upgrading of the Metz– Luxembourg line.

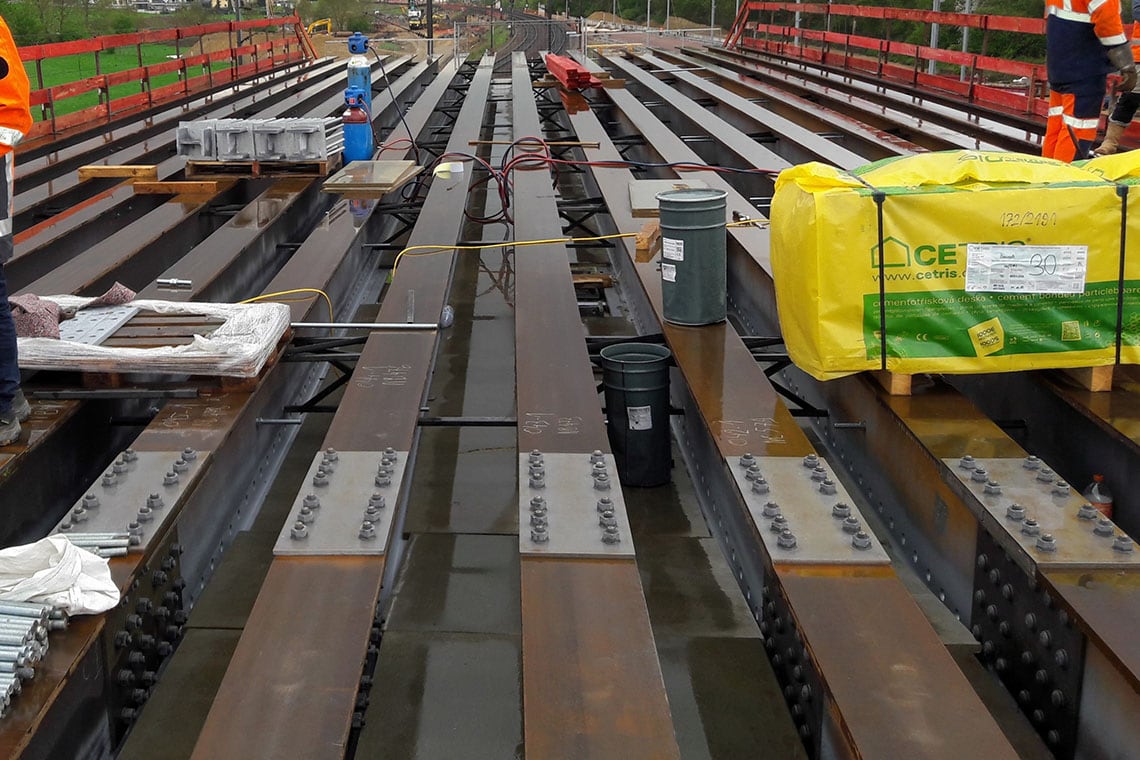

TCBs have been successfully installed in the High Speed Rail connection between the French city of Metz and Luxembourg City. To support High Speed Rail with speeds of 320 km/h the existing track needed to be ‘smoothed out’ therefore the shorter curves in the track were lengthened along three areas of track at Bettembourg (Luxembourg). Greenkote TCBs are used in the junctions, connecting these stronger and longer ‘H’ beams.

This is in readiness for the TGV (Train à Grande Vitesse - High Speed Train) built for CFL (Chemin de Fer du Luxembourg / Railroads of Luxembourg) with Main contractor Felix Giorgetti installing approximately 30,000 M24 Greenkote TCBs.

Tension Control Bolts Ltd are pleased to see support high speed rail projects globally

Bridges